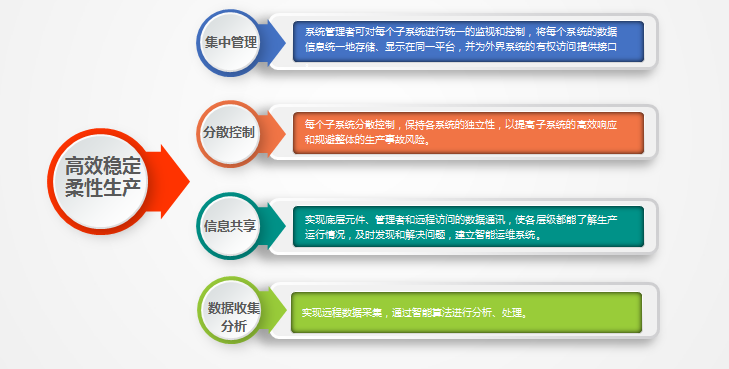

through the intelligent control architecture of centralized management, decentralized control, information sharing and data collection and analysis, the intelligent control system of our company's production line can ensure the stable operation of the production line, realize the flexible and automatic production of products, and meet the market demand of small batch and multi batch。

from the structure, it is divided into three levels: intelligent operation and maintenance layer, production management layer and field control layer.

the objective of the intelligent operation and maintenance layer is to ensure the normal, reliable and operation of the production line, so that the project personnel can clearly understand the operation of the whole system equipment, ensure rapid response to emergencies and demand changes, and ensure the integrity of the system; realize the real-time monitoring, feedback and adjustment, data collection and analysis, anomaly detection, fault alarm, trend prediction and analysis functions of the whole system.

the production management layer includes the upper computer containing the configuration screen and the plc controller collecting the field data. on the one hand, it can feed back the field generated situation to the screen in real time, which is convenient for manual monitoring and analysis; on the other hand, it can send instructions to the field control layer to guide production. the communication between production management layer and control layer is through ethernet, which has high real-time performance.

the field control layer refers to the control subsystem and various intelligent devices and components arranged on the production site. the subsystem of the field control layer feeds back the collected field data (frequency, current, temperature, pressure, flow, etc.) to the production management layer, which records the feedback data into the database and prompts the abnormal data in the form of alarm and redistributes the task of the subsystem. the field control layer can collect ethernet / serial port / hardwired signals and other wide area signals.

the control system is mainly composed of the following aspects:

plc / dcs control system: mainly uses s7-1500 / 1200 series programmable controller of siemens company of germany, or hollysys dcs control system. ethernet communication realizes automatic control of electrical equipment in the production line.

upper computer monitoring system: dell commercial desktop computer real-time monitoring, configuration software (wincc) or industrial monitoring system configuration software (mcgs).

motor control system: schneider and chint low-voltage electrical appliances are selected to form the control system of all motors in the production line.

local manual control system: hmi human-computer interface is adopted for human-computer interaction, which is used for local debugging, maintenance and status display of main equipment.

according to the needs of customers, the intelligent control system of the production line has enterprise level mes or erp system interface and intelligent operation and maintenance data center interface, which can realize the sharing and unified management of project and enterprise information with the enterprise.

english

english

address: no.9960, qushan road, chengguan street office, linqu county, shandong province

address: no.9960, qushan road, chengguan street office, linqu county, shandong province  service hotline: manager du 86 18853622696 / 0536-3717317

service hotline: manager du 86 18853622696 / 0536-3717317 e-mail:831785@sdhylf.com record number:

e-mail:831785@sdhylf.com record number:

about us

about us nwes

nwes